Livestock manure during breeding

Treatment Cost : $20/ton in Korea

$1.6 trillion / year

CO2 Emission : 18 million ton / year

Waste from the slaughter process

Treatment Cost : $130/ton in Korea

$20 billion / year

CO2 Emission : 0.2 million ton / year

Food waste

Treatment Cost : $160/ton in Korea

$800 billion / year

CO2 Emission : 9 million ton / year

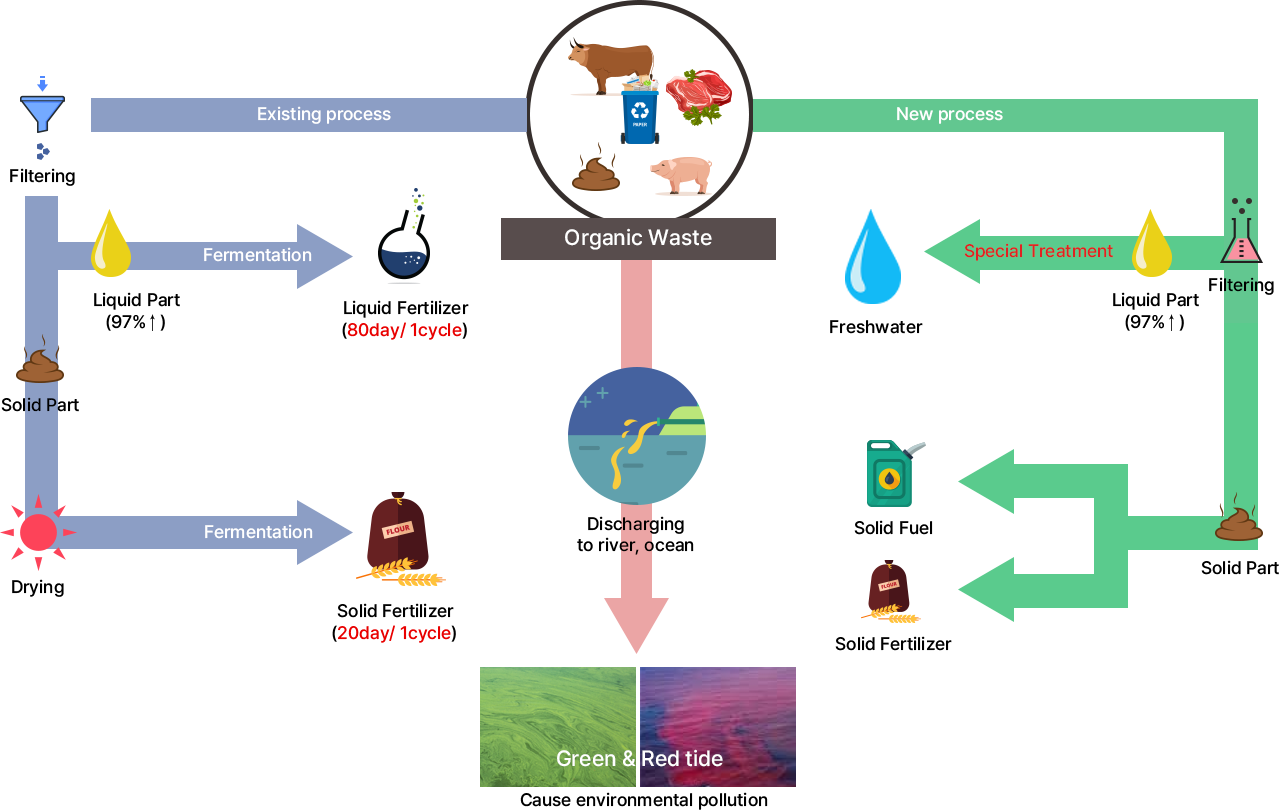

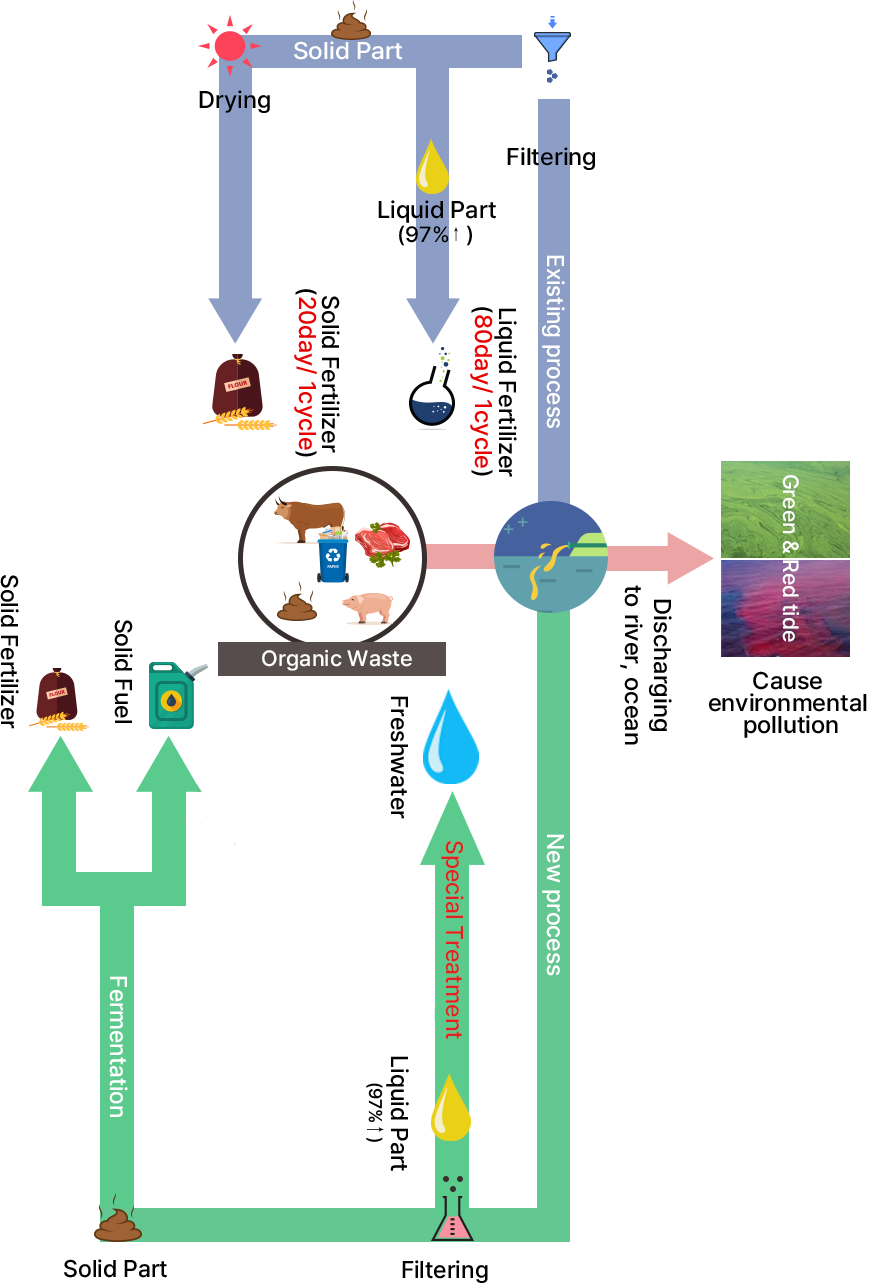

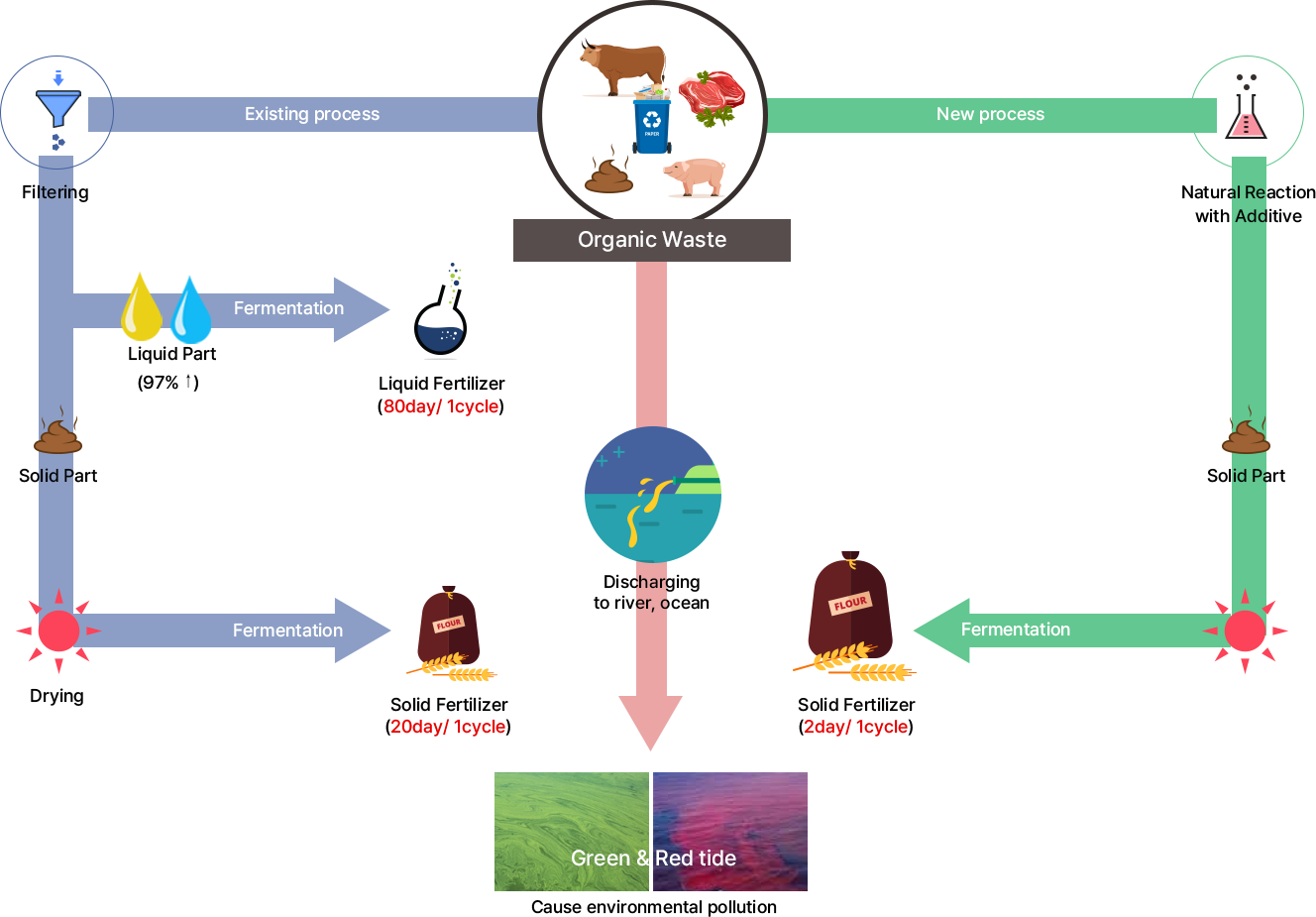

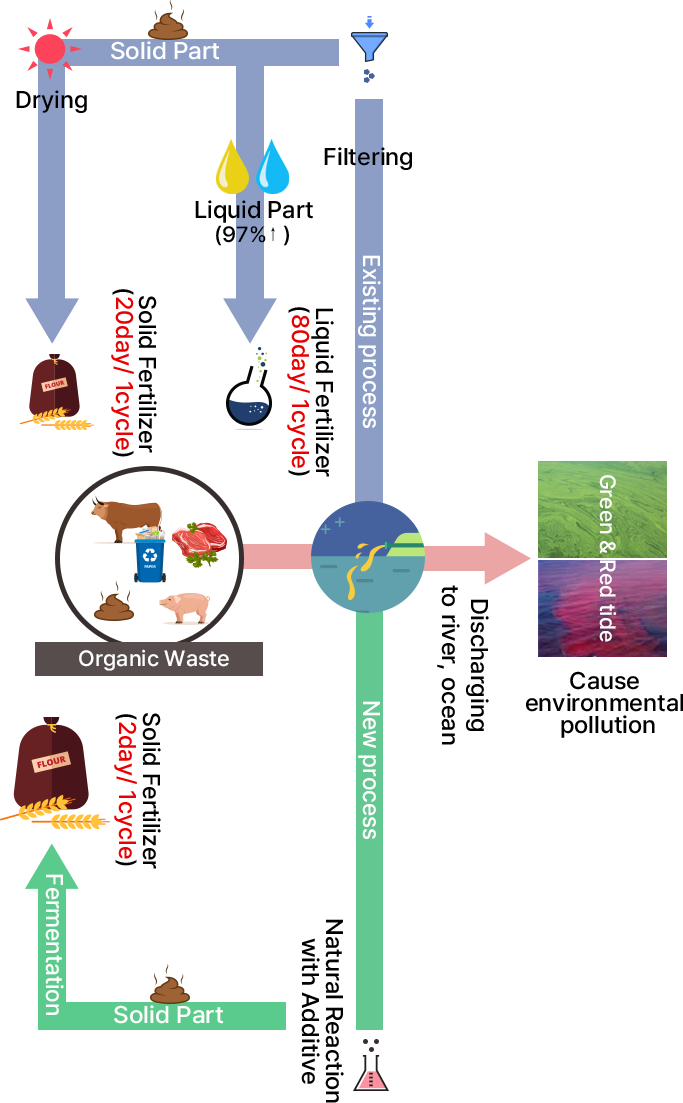

Fermentation – Fertilizer production

- Reduced liquid fertilizer

- Increased compost Production

Feeding through blood coagulation

Food/medicine additive

Use of waste resources as natural

gas Biogas (CH4, H2, etc.)

Organic Waste Circulation

‘ONI STOP’ Project

3D Video

‘POO-GREEN’ Project